Product Engineering

Move Fast and Make Things

Product and Development Teams that worked with us saw 90% Product Cost Reduction, 84% On-Time, On-Budget Completion, and 89% Expansion into New Markets.

What we do

From concept to launch, we build products that perform, scale, and succeed.

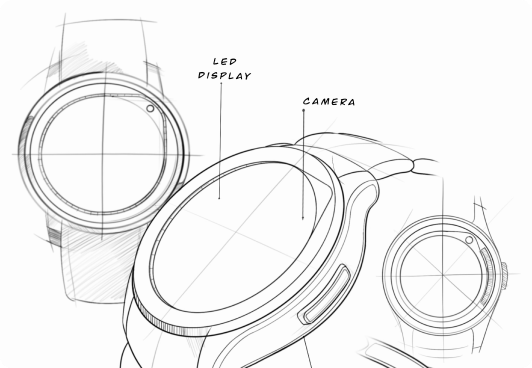

Industrial design integration

Art meets Reality. We apply mechanical engineering services to fully understand, maintain and refine the ID through development and manufacturing, while improving mechanical integrity and manufacturability. This allows many aspects of the design to be proven and optimized prior to prototype manufacture, eliminating the requirement for costly redesigns at a later stage within the process.

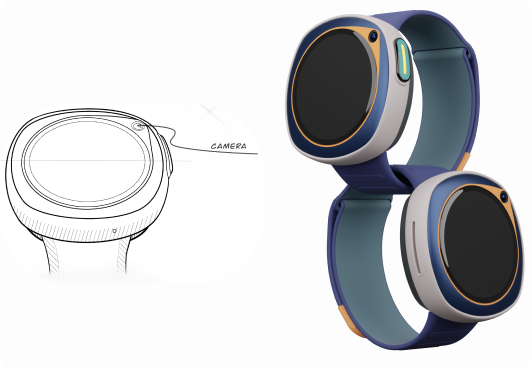

Quickly realising an engineering concept

Through advanced product engineering, your early ideas are turned into feasible embodiments, building a concept, its features, components, mechanisms, and sub-assemblies. By prioritizing frequent prototyping and testing, we de-risk your product development strategy and build confidence early on that your product will meet performance requirements.

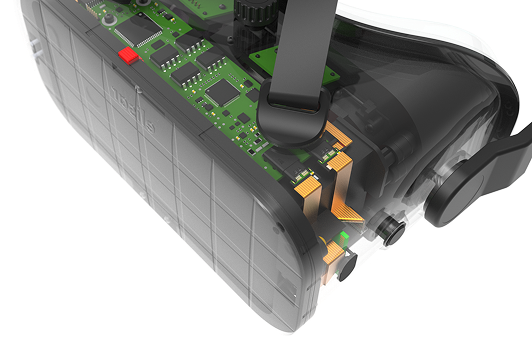

Regulate Device Development

Highly regulated markets like healthcare and aerospace require strict compliance. We deliver mission-critical products that meet stringent safety, regulatory, and usability needs, backed by our regulatory compliance engineering expertise.

Converging to scalable production methods

Your product is designed from the outset with design for manufacturability (DFM) and design for assembly (DFA) principles. Sales volumes, pricing power, and market fit are matched with scalable manufacturing and assembly considerations. Our engineers break an assembly down into its component parts to produce a CAD database and bill of materials ready for production.

Production liaison

We engage with your supply chain: injection moulding, die casting, metal stamping and forming, PCBA partners, during the entire process to ensure the design is built cost-effectively and with quality to match. Don’t have a supply chain? Don’t worry, we can help you set one up, oversee initial production runs, and be on-call during ramp-up. We’re your on-ground partner in manufacturing engineering services.

Engaging Work. Inspiring Results

Your Products Engineered to Perfection.

800+

Projects

27

World’s Firsts

$500Mn+

Revenue Delivered

50Mn+

Products shipped

What Benefits You Will Get

Fast Track Innovation

We push boundaries and champion innovation with a proven track record. Our rapid product development services ensure you hit the market before your competitors, with zero compromise on quality.

Crush Competition

Our diverse, award-winning team is battle-tested to ensure your product is built for success. Launch products that set new benchmarks with integrated industrial design engineering and robust product performance.

Resource Revolution

Struggling to build the right team? Access our on-demand engineering experts and upskill your internal teams through collaboration with a constantly evolving pool of professionals across FEA, CAD modeling, and more.

“Faced with polishing our portable visual field analyzer, Bang Design delivered market-ready magic. They mastered industrial design, styling, and engineering, even sourcing key vendors. The result? A functional, business-aligned triumph. Bang Design was instrumental in AVA’s success.”

Subscribe now to get started

Get unlimited access to:

Our Process

What happens after you start?

Step 1

Design Evaluation

We begin with a detailed understanding of your product requirements. This is captured in a comprehensive Product Requirement Document (PRD) and Feature Prioritization Matrix—key tools in every successful product lifecycle management plan.

Step 2

ID Integration + Re-configuration

On 3D CAD, we develop a full system layout with integrated ID, part break-up, electrical components, and assembly methods. Mechanism and kinematic engineering are iterated here, ensuring the product development engineering phase is aligned with manufacturing goals.

Step 3

Evaluation + Prototyping

We build prototypes through our trusted partner network to test critical functions. These cover mechanical engineering, usability testing, interference checks, and aesthetic evaluation. It’s where form, function, and user experience meet.

Step 4

Refine + Document

We execute detailed designs and document parts for mass production. This phase includes 3D CAD geometry, 2D documentation, and a complete bill of materials. For regulated devices, we also produce compliance-ready prototypes.

Step 5

Ramp-Up

We work with manufacturers to review tooling, samples, and production tests. Expect several iterations (T0 to T4) as we refine for production efficiency and product quality. We're also happy to assess your partners’ quality management systems or stay on as your engineering support team.

Insights

Trade, Technology and The Allure and Illusion of Industrial Policy

Danbo: The Cardboard Robot That Conquered the World

How Do You Build Something People Want?

Why Are Feature Phones Making a Comeback?

Frequently Asked Questions

What are product development services?

Product development, or often called New Product Development (NPD) is the process that straddles planning, research, strategy, ideation, design, prototyping, testing, refinement, and readiness for manufacturing to transform a conceptual idea into a fully-functional, market-ready product. It encompasses product design, product engineering, service and digital design, and often production to complete the development cycle.

What’s Next after Product Development is Done?

Provided you are adequately capitalised, this is a happy place to be. You can either (1) sell directly to customers, or (2) license your product to a brand that already has distribution muscle, or (3) convince manufacturers with scale to offer your product to their existing brand customers. In all cases, you would want to prove that your product has traction in the market. Whichever path you choose, we have you covered with our support services.

How much do product development services cost?

Every project is different. Even NPD programs adjacent to existing mature market products can be massively complex, and require high capital outlays. While many new programs can be brought to market in a fraction of the estimated cost. With our Micro-ODC and Subscription models, you get the best of all three – capital efficiency, high-quality and time efficiency for the resources.

I am a small manufacturer. Will you do design and engineering development for or with me?

We are the best product development services firm loved by small product and manufacturing businesses. We infuse bravery into all your programs – whether something entirely new, or an incremental update to your existing products, our engagement models provide you with the best value on your investment.

How is Bang Design Different from other product engineering firms?

Our purpose-built in-house teams and extended resource pools are headed by some of the most creative and experienced product development experts in the business. Whether we are augmenting your internal team or truly owning the innovation and development process, our customers trust us to get the job done. Product Engineering is what we love to do. We focus the practice, attracting and hiring resources, and training and investments, on being the best flat-rate product engineering platform in the World.

What can I expect in the Industrial Design Integration service?

- Component configuration optimization

- Design feasibility review

- Mechanical product architecture

- Ergonomics and fit prototyping

- Complex CAD surfacing, C3 continuity

- Creative assembly and finish strategies

What can I expect in the engineering concept service?

- Proof of Concept Prototypes

- Mechanism design

- Component packaging studies

- Mechanical product architecture

- Functional Decomposition

- Intellectual Property Creation

- Technical Feasibility Studies

- Material Selection

- Structural design

What can I expect in the Regulated Device Development service?

- Verification & Validation plans and execution

- Client QMS support

- IEC 60601-1 safety requirements

- Coordinating pre-clinical trials with IBUs

- Coordinate Short-run builds for clinical trials

- Liaison with ISO certified suppliers & testing labs

- Biocompatible material selection

- Production Level Drawings

What can I expect in the Production Liaison service?

- Preparation of RFQ packages

- Vendor capability evaluation

- Prototype vendor management

- DFM/DFA negotiations

- Engineering sample reviews

- Tooling design and part sample review

- Mechanical test oversight

- Onsite production ramp support

What can I expect in the Converging to scalable production method service?

- Top-down driven 3D CAD Database

- Schematics and layouts for

- Hardware Design for Manufacturing and Assembly (DFMA)

- Plastics, Sheet Metal and pressure die cast parts

- 2D drawings

- Engineering Reviews

- Assembly fixture design

- BOMs and assembly instructions

- Tolerance Analysis and GD&T